Modification Guide for Evolution Table SawsUpdated 5 months ago

The miter tracks on Evolution table saws are non-standard, being shallower, 15/64” or 7mm, compared to a typical depth of 3/8”. This was a design decision made by the manufacturer due to the slider on the saw. As manufactured, the Thin Rip Gauge sits too high in the miter slot and will not lock down. There are two ways of solving this problem.

Solution #1

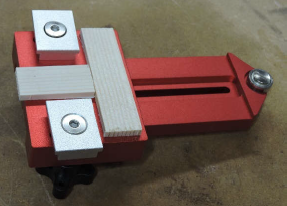

The first solution is to add two thin pieces of wood, about 1/8” thick, to the underside of the gauge’s body. They can easily be adhered to the gauge with double-sided masking tape. The pieces of wood will raise the gauge up off the table, making it possible for the knobs to be tightened, locking the gauge into place.

Please note that when using this method, the bearings which make contact with the wood being cut will be raised up off the table about 1/8”. This does not affect the function of the gauge in normal operation.

Solution #2

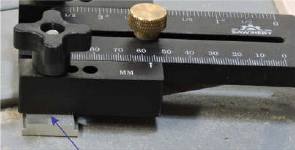

The basic problem is that the blocks that go into the miter slot are too high for the miter slots on the Evolution table saw. They can be removed from the gauge, and the screws removed.

Without the screws in place, the top of these blocks can be ground off, removing roughly 1.5mm or 1/16”. This grinding can be done with a grinding wheel, but if a belt sander is available, it is easier to grind them flat on the belt sander.

Use some sort of clamp or vice grips to hold the blocks while grinding them, as the aluminum will become hot.

Once the tops are ground off, the Thin Rip Gauge can be reassembled and used with the Evolution Table Saw. This will not prevent it from being used with other table saws.